A Complete Guide to Workplace Safety Signs

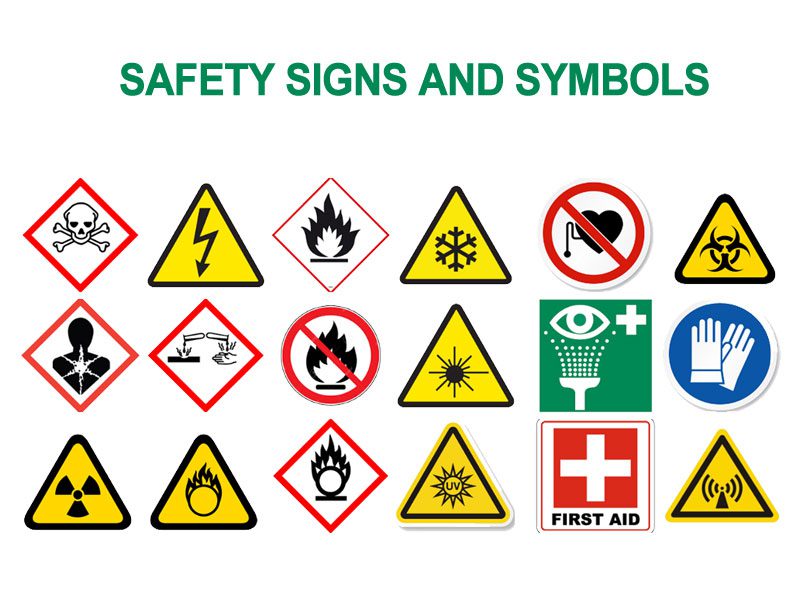

Safety signs are used across industries to promote workplace safety. They reduce accidents and injuries by serving as easily recognizable indicators of potential hazards. As such, industry partners must ensure that proper and compliant signage is displayed according to the appropriate standards. This extensive guide to workplace safety signs, their meanings, and best practices for use is

designed to help you navigate the complex web of rules and regulations that govern their display. Use it as a resource to help guide your workplace safety policies and safety sign buying decisions.

Safety Signs in the Workplace

There are many different applications for safety signs in the workplace. In general, they serve one of the following three main purposes. To Provide Direction: Some workplace signage is used to designate specific locations or traffic patterns. This includes smoking area signs, hand washing signs and room name signs. Exit

signs and barricade signs ensure you know where you can and can’t go. This ensures work zone safety by directing people and items to appropriate areas. To Provide General Information: When you need to convey information or instructions, or you want to share safety quotes for work, general information signs are a useful tool. Instructional

signs detail safety topics for work on a specific machine or operating line, and house keeping signs direct workers to follow proper sanitation and hygiene practices. To Warn of Potential Dangers: Some signs are displayed to warn of increased risk of danger. These should always be color-coded according to the level of risk and worded to clearly indicate a potential hazard. Funny safety signs have no place here. Be direct and use positive, action- oriented wording to get your message across quickly and clearly. Safety Signs: Color Coding and Meaning Colors play an important role in conveying safety and road work sign information quickly and effectively. The American National Standards Institute and Occupational Safety and Health Administration developed standards to assign meaning to specific colors. This helps ensure that

signage is consistent across industries, and that company messaging is delivered in a concise manner. Red: The color red is used on DANGER signs and STOP signs. It conveys a high risk of danger

that could result in injury or death. Fire suppression equipment and emergency stops or alarms are red to increase their visibility.

Orange: Moderate risks of danger, like those posed by equipment or sharp edges, should be designated by orange WARNING signs. Road construction signs, under construction signs and other traffic safety signs are printed on an orange background. Yellow: According to OSHA standard 1910.145(d)(4), situations that require caution are denoted with yellow-and-black CAUTION signs. No trespassing signs designed to keep people from potential harm may use this color combination. In addition to trespassing signs, hazard and flammable material storage containers and doorway obstructions will be marked with yellow CAUTION signs. Fluorescent Orange or orange-red with contrasting lettering is used to denote a biological

hazard. Green: Green safety signs mark first aid and safety equipment. Blue: A blue background on safety signs indicates that a piece of equipment is under repair andshould not be started or moved. Purple: Purple is reserved for safety signs marking radioactive material and hazards. Thesearegenerally on a yellow background with a graphic clearly designating the hazard. Types of Safety Signs

There are three main classifications of safety signs according to OSHA. These are:

- Danger signs indicate a serious immediate threat that will cause grave injury or deathif

it is not avoided. They will be a combination of red, black and white with the wordDANGER across the top. Orange warning signs may be used to draw attention toa lessserious or less immediate threat. - Caution signs denote the risk of a minor or moderate injury. They have a yellowbackground with black upper panel, borders and lettering. The upper panel displays theword CAUTION, sometimes accompanied by a graphic. 3. Safety instruction signs are informational signs that tell workers about policies andprocedures. They may have instructions for hygiene practices or equipment operationandshutdown steps. Instructional signs must be white with a green upper panel with whiteletters. Additional lettering and graphics are black on the white background. There are several other, smaller categories of safety signs including: General safety signs may be road safety signs, construction safety signs, no smokingsigns or electrical signs to warn of danger or shutoff locations. Admittance signs and no trespassing signs detail who can and cannot enter a designatedarea. Fire safety signs will have white lettering and graphics on a bright red background. Theyare easy to spot and mark fire extinguishers, hoses and other fire suppression systems. Non-hazard signs include traffic signs and safety area directional signs. For temporary applications, lightweight safety tags may be used in place of signs. They must

comply with all color and design requirements as laid out under OSHA and ANSI standards. OSHA Regulations

The Occupational Safety and Health Administration is the main governing body for developingU.S. regulations and standards for workplace safety. OSHA standards and regulations layout thespecific requirements for signage. Failure to comply with those requirements puts you inviolation of federal workplace safety laws.

OSHA describes a standard or regulation as “… a regulatory requirement established andpublished by the agency to serve as criteria for measuring whether employers are in compliancewith the OSH Act laws. OSHA standards are published in Title 29 of the Code of Federal

Regulations (CFR) and are divided into separate standards for General Industry, Construction, and Maritime.” Safety warning signs play a large role in maintaining workplace safety. They must be postedinaccordance with all requirements of your specific industry. OSHA 1926.200(a) states that OSHAsigns must be “visible at all times when work is being performed, and shall be removed or

covered promptly when the hazards no longer exist.” They must be posted where they are visiblefrom a set distance, in most cases five feet. OSHA-compliant safety signs will be made of a material that is appropriate for the locationwhere they are posted. In most cases, that will be a sturdy material designed to withstandconditions in your facility such as aluminum or heavy plastic. Some safety signs are alsoavailable in adhesive vinyl for direct application onto a wall, piece of equipment or another

smooth background. They must have “rounded or blunt corners and shall be free fromsharpedges, burrs, splinters, or other sharp projections. The ends or heads of bolts or other fasteningdevices shall be located in such a way that they do not constitute a hazard” as listed under OSHA1910.145(d)(1)

PPE signs serve as a reminder for workers to wear appropriate gear such as glasses, helmets, gloves or masks. Biohazard signs serve as a further warning to take proper precautions. In some cases, signage may be required to inform the public about potentially hazardous

situations. Community safety signs indicate access requirements, entrances and exits andhelpwith wayfinding. They are often brown, blue or green depending on their function. Fluorescent

yellow-green is approved for pedestrian, bicycle, and school crossing warning signs. Military & ANSI Standards

In addition to OSHA and ANSI standards, all safety and security signs used in military

applications must meet standards set forth in MIL-DTL-15024F. Its specification sheets outlineextensive physical requirements for materials, design and packaging of all military signs, platesand equipment tags. All materials for Military and federal government applications must also adhere to federal

procurement guidelines. The Department of Defense Index of Specifications and Standards andthe Office of Federal Supply and Services Index of Federal Specifications, Standards andCommercial Item Descriptions are useful resources for navigating the purchasing process of

appropriate OSHA and ANSI safety signs. U.S. General Services Administration Global Supply regulations state that anymaterial that can be classified as a physical or health hazard should be markedwithspecial chemical safety signs. Hazardous materials are commonly referredtoasHAZMAT and labeled with safety hazard signs bearing that description. Materialsthat generally fall under HAZMAT guidelines in military and civilian applicationsinclude chemicals that are known to be: Toxic or highly toxic agents

Carcinogens

Harmful to reproductive processes

Irritants

Corrosives

Damaging to the lungs, skin, eyes, or mucous membranes

Combustible liquids

Explosives

Compressed gases

Flammable liquids or solids

Unstable at rest or when exposed to water

ANSI signs should always be used to denote these items and proper storagelocations. Emergency supplies should be marked with first aid signs that arehighlyvisible in case of accidental exposure. Confined spaces, defined as a space that is big enough to fully enter and performwork in, but has restricted access and is not designed for continuous use, must bemarked with appropriate confined space signs. OSHA standard 1910.146addressespermit-required confined spaces that may contain hazardous material.

Where to Place Safety SignsProper sign placement increases its effectiveness. In general, no sign should interfere withtheplacement or message of another sign. It should also be visible from a set required minimumdistance. The best way to determine whether you are meeting requirements for sign placement is tocheckthe appropriate local and OSHA standards. While you may need additional signs dependingonyour specific situation, you can get started by checking your signage to see if it meets this basicguide to workplace safety signs: All evacuation routes are marked with appropriate evacuation signs. (Add periods toall

bullets) Exits from individual rooms and buildings are clearly marked with red and white exit

signs. Areas where food is prepared display hygiene and food safety signs. Hazardous materials are clearly labeled with appropriate HAZMAT designations. Equipment and general hazards are all marked with proper warehouse safety signs. All restrooms are marked with restroom signs. Having the proper signs posted in the correct locations helps keep workers, customers andvisitors safe. This guide to workplace safety signs helps you know which signs you need soyoucan post them where people will easily see and recognize them. The 6 Types of Safety TagsYouNeed

When you think about your overall safety program, do you think about communication?

Communication is a key element to proper safety. Some of the most overlooked methods of

safety communication are different types of safety tags. If you think of safety tags and your mind jumps to lockout/tagout procedures, that’s good! Thoseare very important tags to have and to use. But, there are other tags that you need in the

workplace. Here are six types of safety tags you need and why they’re important. Lockout/Do Not Operate Tags

Most companies have machines. And, like all machines, that equipment needs work fromtimetotime. It may be a significant project, or it could be a simple maintenance issue. In either case, you will shut down equipment and machinery for someone to work on it safely. That’s where lockout-tagout (LOTO) tags come in. Lockout/tagout tags let other workers knowthat the machine is currently being serviced and that they should not try to turn it on. In 2019, lockout/tagout was the 4th most commonly cited violation by OSHA. The penaltyfor

lockout/tagout citations in 2019 was as much as $13,260 per violation. Additional fines of upto$13,260 are added per violation per day past the deadline to fix the issue. Ladder & Scaffold Tags

Falls are one of the most common causes of workplace injuries. Improperly used, constructed, ormaintained ladders and scaffolding are accidents waiting to happen. Scaffolding and ladders came in #3 and #6 on OSHA’s most commonly cited violations for - Ladder and scaffold tags are a big part of the solution. These tags communicate to

employees which ladders and scaffolding have been inspected, which are safe to use, andwhichare unsafe. OSHA citations for ladder or scaffolding violations can cost $13,000. Additional fines are addedfor each day past the deadline to remedy the issue. Having the proper type of tags in place

improves communication and reduces the risk of improper use of ladders and scaffolding, whichreduces your risk of a hefty fine. Inspection Tags

Regular equipment inspections reduce the chances of equipment failure and worker injury–andhelp ensure your equipment will be ready for use when needed. But, you need to keep trackof

your inspections, so you know when they are done and what the results are for each one. Inspection tags make it easy. These types of safety tags are made so you can identify the pieceofequipment, the location, as well as the date of each inspection, and the name of the personwhosigned off on it.

Some items, like portable fire extinguishers, are required to have an annual maintenance

inspection. Others, like forklifts, need daily inspections. Keeping inspection tags on handandonequipment is an easy way to keep track of when each item is inspected and by whom. Machine Tags

Machines are an integral part of many businesses, but they also come with significant injuryrisk, especially when they are not in good working condition. Keep tags on hand that will alert

employees when a machine is not operating or should not be turned on for any reason. Without

the proper machine safety tags, a worker could fire up a faulty machine without knowingit andcause injury to themselves or others in the area. Barricade Tags

Barricades serve a simple purpose, to keep people out of a restricted area. Barricade tags areagreat way to add a little more information to the situations. By adding barricade tags, you can alert workers to the reason the barricade is there, whoisauthorized to enter, and who is in charge of the barricade should there be any questions. Confined Space Tags

Working in confined spaces adds an extra level of danger. That’s especially true if that spacehasone of the following OSHA recognized hazards:

a potentially hazardous atmosphere. material that can engulf an entrant. walls that converge inward or floors that slope downward and taper into a smaller area whichcould trap or asphyxiate an entrant. other serious physical hazards such as unguarded machines or exposed live wires. A confined area meeting any of these criteria must be identified by the employer whoisobligated to inform employees who may be exposed, of the existence and location of suchspacesand their hazards.

Confined space tags help to identify these areas, clearly marking them as a “permit-required”workspace. Small Tags That Make a Big Difference

Although safety tags are less than 6 inches tall, they can have a big impact in your workplace. Proper tagging throughout your facility is a key component of a safety program. Not onlydotagscommunicate vital information, they are required by OSHA regulations and can saveyourcompany a lot of money in fines. From equipment inspections to confined spaces, these 6 different types of safety tags helptokeep your team safe and your workplace free from costly accidents. KNOW ABOUT SAFETYANDWARNINGLABELSLabeling is an important part of the packaging and branding a product. While a label canbecreatively designed to suit your business needs, it must have basic information regardingthecontents, date, weight, and so on. This is common for almost all products. However, therearesome products that require safety and warning labels as part of law and regulation. For instance, some hazardous materials, alcohol, cigarette packs, and so on require safety and warninglabels as part of different laws. Most of the time, the content, color, and so on are specific. Thispost discusses the details of these labels.

Types of Safety and Warning Labels

There are various types of safety and warning labels based on products and their legal mandates. Here are a few mandatory safety and warning label types:

Safety labels for hazardous materials:

Packaging and transportation of hazardous chemicals, acids, abrasive materials, and so onneedsto be done according to the required law and regulation. This is crucial because of the sheertoxicity and other harmful properties of these materials. Alcohol labels:

There are side effects and health issues related to excess consumption of alcohol, andalmost

everyone knows about this. However, alcohol manufacturers are required to print a statutorywarning on their products regarding age limit, excess consumption, and the repercussionsonhuman health. Also, the exact content on the label would differ based on the type of alcohol suchas beer, wine, and so on. The same applies for cigarettes and any form of tobacco or nicotineproducts. Prop 65 regarding marketing of goods:

A few goods are manufactured to be sold in specific states and regions, and the Prop65lawclarifies the same. If a product is to be sold in select states, the same needs to be mentionedonthe label on its packaging. It is illegal to sell these products outside of the mentioned statesorregions or countries on the label. Specific drugs:

Some drugs like cannabis are legalized in specific states in the US, while in most other statesthey are banned. The required warning and safety content needs to be mentioned on suchdrugpacks with approval from local and state governments. Medicines:

Some medicines cannot be sold over the counter and need a doctor’s prescription. It is mandatorythat this content is mentioned on the medicine packaging, and the pharmacy salespersoncannot

sell it without reading the prescription. Certain medicines and medical equipment alsohavelabeling norms, especially when in transit. Child safety warning labels:

Products such as plastic toys made for children need to have a safety label saying the material

used is safe for kids. This is primarily because children have a tendency of putting toys intheirmouth or sucking their fingers. This applies to other accessories for kids such as car seats, plasticbottles, and so on. Also, the manufacturer needs to mention safe usage guidelines onthepackaging. If you manufacture a product that requires safety and warning labels, ensure you source it fromasupplier who is experienced, aware of the legal implications if this is not done correctly. Performance Label Company (PLC) provides various safety and warning labels complyingwithspecific standards. The company offers these labels with a superior quality adhesive so that theydo not come off easily and are waterproof